-

Hydraulisk presse og produksjonslinje for slipemidler og slipemidlerHydraulisk presse og produksjonslinje for slipemidler

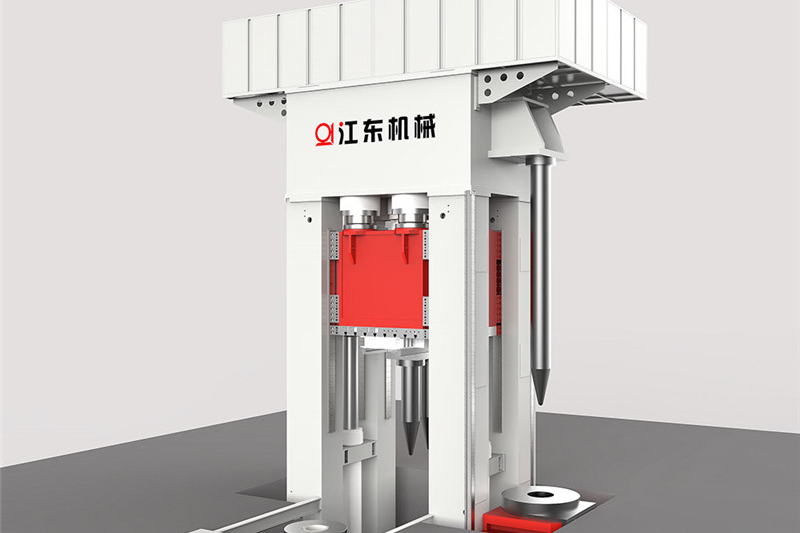

Vår hydrauliske presse for slipe- og slipeprodukter er spesielt utviklet for presis forming og forming av slipeverktøy laget av keramikk, diamanter og andre slipematerialer. Pressen er mye brukt til å produsere produkter som slipeskiver. Maskinhuset til den hydrauliske pressen finnes i to typer: modellen med liten tonnasje har vanligvis en trebjelkes firesøylesstruktur, mens den kraftige pressen med stor tonnasje har en ramme- eller stableplatestruktur. I tillegg til den hydrauliske pressen er det forskjellige hjelpemekanismer tilgjengelig, inkludert flyteanordninger, roterende materialspredere, mobile vogner, eksterne utkastanordninger, laste- og lossesystemer, formmontering og demontering, og materialtransport, alt rettet mot å oppfylle kravene til presseprosessen og forbedre produksjonseffektiviteten.

-

Metallpulverprodukter som danner hydraulisk presse

Vår hydrauliske presse for pulverprodukter er spesielt utviklet for å forme et bredt spekter av metallpulver, inkludert jernbasert, kobberbasert og diverse legeringer. Den er mye brukt i industrier som luftfart, bilindustri, elektronikk, apparater og instrumentering for produksjon av komponenter som gir, kamaksler, lagre, føringsstenger og skjæreverktøy. Denne avanserte hydrauliske pressen muliggjør presis og effektiv forming av komplekse pulverprodukter, noe som gjør den til en verdifull ressurs i ulike produksjonssektorer.

-

Vertikal produksjonslinje for tegning av gassflasker/kulehus

Den vertikale produksjonslinjen for tegning av gassflasker/kulehus er spesielt utviklet for produksjon av koppformede (tønneformede) deler med en tykk bunnende, for eksempel forskjellige beholdere, gassflasker og kulehus. Denne produksjonslinjen muliggjør tre viktige prosesser: stukking, stansing og trekking. Den inkluderer utstyr som en matemaskin, mellomfrekvensvarmeovn, transportbånd, materobot/mekanisk hånd, hydraulisk presse for stukking og stansing, glidebord med to stasjoner, overføringsrobot/mekanisk hånd, hydraulisk presse for trekking og materialoverføringssystem.

-

Horisontal tegningsproduksjonslinje for gassflasker

Den horisontale produksjonslinjen for gassflasker er designet for strekkformingsprosessen av superlange gassflasker. Den bruker en horisontal strekkformingsteknikk, bestående av linjehodeenhet, materiallasterobot, horisontal presse med lang slaglengde, materialtilbaketrekningsmekanisme og linjeendeenhet. Denne produksjonslinjen tilbyr flere fordeler som enkel betjening, høy formingshastighet, langt strekkslag og høy grad av automatisering.

-

Hydraulisk presse for plater med rettetang

Vår hydrauliske portalrettingpresse er spesielt utviklet for retting og forming av stålplater i industrier som luftfart, skipsbygging og metallurgi. Utstyret består av et bevegelig sylinderhode, en mobil portalramme og et fast arbeidsbord. Med muligheten til å utføre horisontal forskyvning på både sylinderhodet og portalrammen langs arbeidsbordets lengde, sikrer vår hydrauliske portalrettingpresse presis og grundig platekorrigering uten blindsoner. Pressens hovedsylinder er utstyrt med en mikrobevegelsesfunksjon nedover, noe som muliggjør nøyaktig plateretting. I tillegg er arbeidsbordet designet med flere løftesylindere i det effektive plateområdet, noe som letter innsetting av korreksjonsblokker på bestemte punkter og også hjelper til med å løfte platene.

-

Automatisk hydraulisk presse for retting av stangmateriale

Vår automatiske hydrauliske portalrettepresse er en komplett produksjonslinje designet for effektivt å rette og korrigere metallstangmateriale. Den består av en mobil hydraulisk retteenhet, et deteksjonskontrollsystem (inkludert deteksjon av arbeidsstykkets retthet, deteksjon av arbeidsstykkets vinkelrotasjon, deteksjon av rettepunktavstand og deteksjon av retteforskyvning), et hydraulisk kontrollsystem og et elektrisk kontrollsystem. Denne allsidige hydrauliske pressen er i stand til å automatisere retteprosessen for metallstangmateriale, noe som sikrer overlegen nøyaktighet og effektivitet.

-

Isolasjonspapp varmpresseformingsproduksjonslinje

Produksjonslinjen for varmpresseforming av isolasjonspapp er et helautomatisert system som består av forskjellige maskiner, inkludert forlaster for isolasjonspapp, monteringsmaskin for papp, flerlags varmpressemaskin, vakuumsugbasert lossemaskin og et automatisert elektrisk kontrollsystem. Denne produksjonslinjen bruker sanntids PLS-berøringsskjermkontroll basert på nettverksteknologi for å oppnå høy presisjon og helautomatisert produksjon av isolasjonspapp. Den muliggjør intelligent produksjon gjennom online inspeksjon, tilbakemelding for lukket sløyfekontroll, feildiagnose og alarmfunksjoner, noe som sikrer overlegen kvalitet og effektivitet.

Produksjonslinjen for varmpressing av isolasjonspapp kombinerer avansert teknologi og presis kontroll for å levere eksepsjonell ytelse i produksjonen av isolasjonspapp. Med automatiserte prosesser og smarte kontrollsystemer optimaliserer denne produksjonslinjen effektivitet og nøyaktighet, noe som gjør den ideell for ulike bruksområder. -

Kraftig hydraulisk presse med én kolonne

Hydrauliske presser med én kolonne bruker en integrert C-type karosseristruktur eller en C-type rammestruktur. For presser med én kolonne og store overflater er det vanligvis utkragede kraner på begge sider av karosseriet for lasting og lossing av arbeidsstykker og former. Maskinhusets C-typestruktur tillater åpen drift på tre sider, noe som gjør det enkelt for arbeidsstykker å komme inn og ut, former å byttes ut og arbeidere å betjene.

-

Dobbeltvirkende dyptrekkende hydraulisk presse

Allsidig løsning for dyptegningsprosesser

Vår hydrauliske presse med dobbeltvirkende trekk er spesielt utviklet for å møte kravene til dyptrekkeprosesser. Den tilbyr eksepsjonell allsidighet og tilpasningsevne, noe som gjør den egnet for ulike bruksområder på tvers av ulike bransjer. Med sine unike strukturelle egenskaper og avanserte funksjonalitet gir denne hydrauliske pressen enestående ytelse og effektivitet i dyptrekkeoperasjoner. -

Hydraulisk presse for karbonprodukter

Vår hydrauliske presse for karbonprodukter er spesielt utviklet for presis forming og forming av grafitt og karbonbaserte materialer. Med en vertikal eller horisontal struktur tilgjengelig, kan pressen skreddersys til den spesifikke typen og matingsmetoden til karbonproduktene. Spesielt den vertikale strukturen tilbyr toveis pressing for å oppnå jevn produkttetthet når høy konsistens er nødvendig. Den robuste rammen eller firesøylestrukturen sikrer stabilitet og holdbarhet, mens avansert trykkkontroll og posisjonsfølende teknologier forbedrer presisjon og kontroll.